In July 2018, led by Xingsha Urban Management Bureau, the landfill leachate treatment project of Hanshan Landfill in Changsha County was completed and was accepted in August. The treated water quality of the project met the general standards of "Standard for Pollution Control of Domestic Waste Landfills” (GB 16889-2008) and the first-level standard of "Integrated Wastewater Discharge Standard" (GB8978-1996).

During the research phase, based on the information provided by Xingsha Urban Management Bureau and the site of the proposed project, the original landfill leachate treatment scale of Hanshan Landfill was 100 cubic meters per day, using anaerobic + SBR process with leachate conditioning. Structures such as regulating tank, blower room, anaerobic + SBR biochemical system and sand filtration tank and built leachate sewage pipes connected to the Bai Sha river. According to the tail water data, the water quality after treatment of this system cannot met the general standards of "Standard for Pollution Control of Domestic Waste Landfills” (GB 16889-2008), so the relevant departments decided to carry out the project.

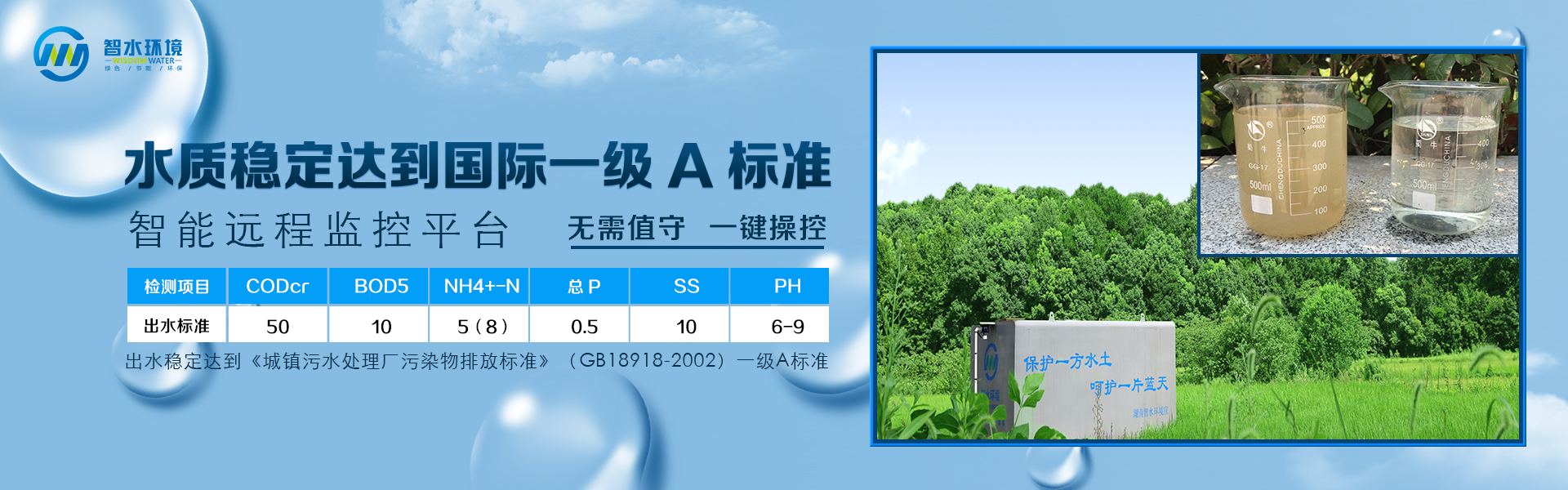

Firstly, we made sure the total treated water volume of the project was 260 cubic meters per day. In the modified process, based on the restoration of the original collection tank function, we eliminated the existing stripping tank, increased coagulation sedimentation and sand filtration pretreatment, and strengthened SS removal. For each indicator we also have implemented the corresponding solution. With regard to the problem of organic matter, ammonia nitrogen, total nitrogen and total phosphorus exceeding the standard, we have added advanced treatment facilities to enhance the removal of organic matter and nitrogen and phosphorus. In the process, we use the fine filtration + UF + RO treatment process to enhance the removal of organic matter, nitrogen and phosphorus. After the ultrafiltration effluent is treated by reverse osmosis, the supernatant after reverse osmosis treatment can achieve complete discharge, and the concentrate is recharged to the landfill. Finally, the remaining sludge pool generated by the collection system is collected and transported to the landfill for landfill.

Advantages of this project:

1) Saving Investment Costs: low device cost and low investment costs;

2) Saving Land: saving floor space;

3) Energy Saving: energy saving, low operating costs;

4) Convenient Operation and Maintenance: fully automated operation management; no professional operators required; remote control;

5) Shorten the Construction Period: the main process can be completed by our device, which greatly shortening the construction period;